Exhibition Notice

Booth No.: To Be Advised

Booth No.: To Be Advised

Date:(12 November 2024 - 15 November 2024 )

Venue: Messe Munich

Location: Germany, Munich

Industry: Electric & Electronics

Automotive Grade Tantalum Capacitors

Polymer Tantalum Capacitors

Dipped, SMD, Low ESR Tantalum Capacitor

Equivalence to AVX, Kemet, Vishay

Booth No.: To Be Advised

Booth No.: To Be Advised

Date:(12 November 2024 - 15 November 2024 )

Venue: Messe Munich

Location: Germany, Munich

Industry: Electric & Electronics

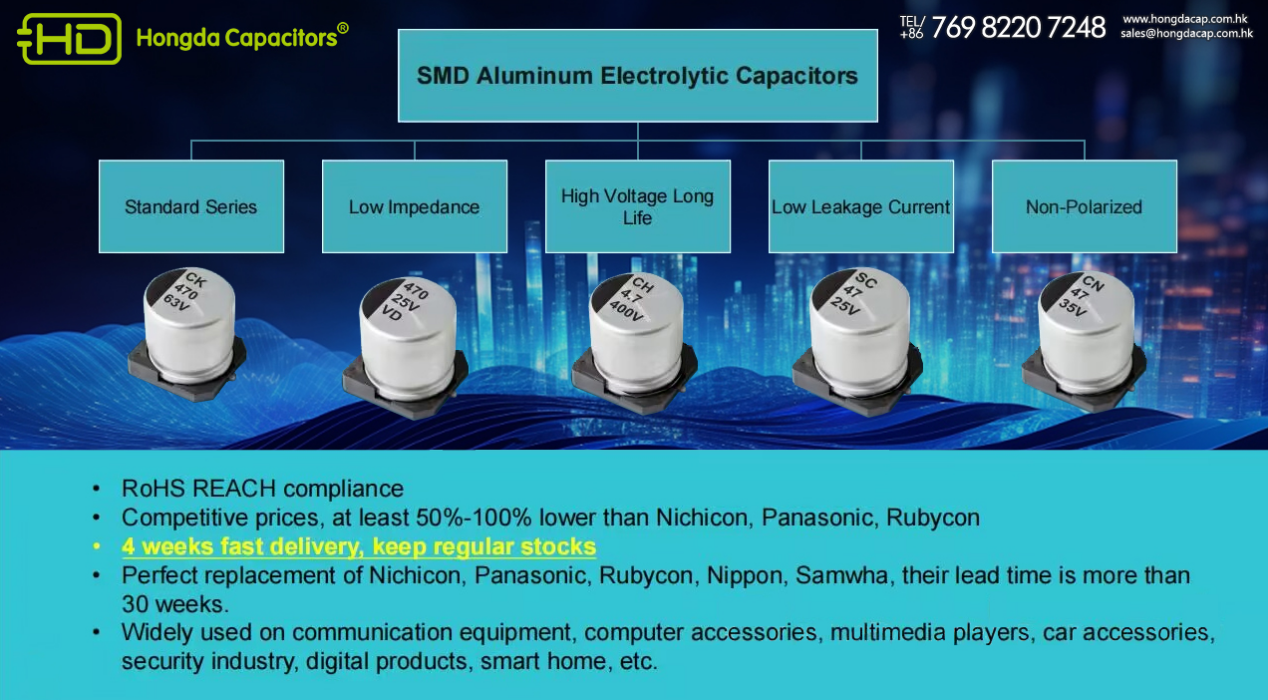

I am SMD (Surface Mount Device) Electrolytic Capacitors, I was born at a big family, I have many brothers and sisters, we are similar style, but in different Dimension & inductance value & impedance value & ripple current Etc..

Thanks to our compact size and excellent performance characteristics, we SMD electrolytic capacitors offer exceptional reliability and efficiency. Whether you are working on consumer electronics, industrial equipment, or automotive applications, we are ready to meet your specific requirements.

Here is the picture of our family.

And our key features and benefits include:

- Miniaturized design: Perfect for space-constrained applications.

- High capacitance values: Ensures optimal energy storage capability.

- Low ESR (Equivalent Series Resistance): Enables efficient energy transfer.

- Long lifespan: Provides extended operational durability.

- Wide temperature range: Suitable for a variety of operating environments.

- ROHS compliant: Environmentally friendly.

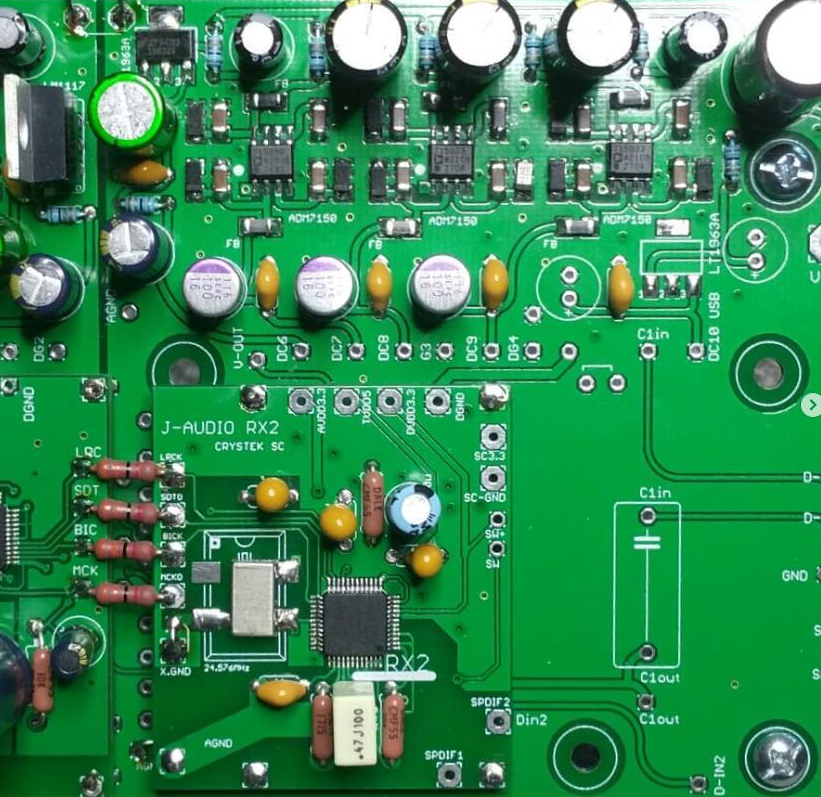

Sometimes we work together for your devises, you may would like to know how we work at your devises?

We are most commonly used in power supplies for decoupling purposes, i.e. to reduce voltage ripple reaching the circuit. They are also used widely in DC/DC switching voltage converters.

We work exactly as the traditional through-hole (THT) capacitors as SMD just indicates the surface mount where the element is made into a block with terminals placed on one surface so it can be paid flat on the board and soldered to the exposed contact pads (the parts of the PCB tracks which are not covered by the protective layer but with a tin for better soldering).

We store and release electrical energy in the form of an electric field between two conductive plates separated by a dielectric material.

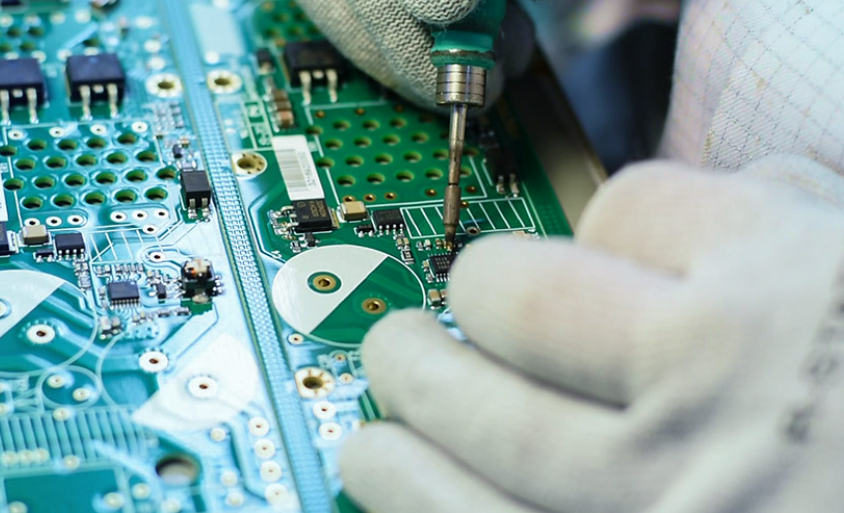

We (SMD) becomes more and more popular since we allows for automated robotized board assembly and soldering.

And how to choose us? our teachers -- the engineers will answer this question.

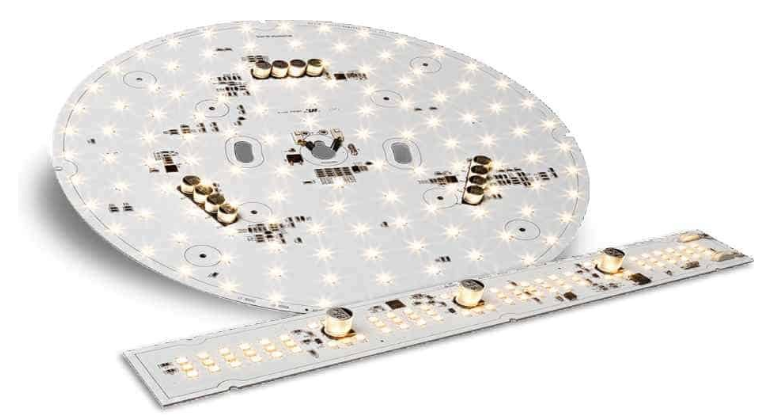

They gave an example for choosing the Right SMD LED PCB

Choosing the right SMD LED PCB for your project is an essential step in designing a successful LED-based system. There are several factors to consider when selecting an SMD LED PCB. These factors include the size, shape, and color of the LEDs and the voltage and current requirements of the project. Moreover, you must consider the overall design of the system. In this section, we’ll explore the key considerations for selecting the right SMD LED PCB.

1. LED specifications

The first consideration when selecting an SMD LED PCB is the LED specifications. It is important to consider the LED color, as this will affect the overall look of the project. SMD LEDs are available in many colors, including red, green, blue, yellow, white, and color changing RGB LEDs.

Other specifications to consider include the LED size and shape. It can affect the overall design of the system. SMD LEDs are available in several sizes. These sizes are 0805, 1206, and 3528, and can be round, rectangular, or square in shape.

2. Brightness Level of the LED

The brightness level of the LED is also important to consider. Brightness level will affect the amount of light emitted by the LED. We can measure the brightness levels in lumens. It can range from a few lumens for low-power LEDs to several hundred lumens for high-power LEDs.

3. Voltage and current requirements

The third consideration when selecting an SMD LED PCB is the voltage and current requirements of the project. SMD LEDs typically require a low voltage and low current to operate. This low voltage requirements ranging from 1.8V to 3.3V and current requirements ranging from 10mA to 30mA.

It’s important to ensure that the voltage and current requirements of the project are compatible with the PCB. Choosing a PCB with too low or too high voltage can damage the LED or the PCB.

4. PCB size and shape

The size and shape of the PCB is also an important consideration when selecting an SMD LED PCB. The size of the PCB will depend on the number of LEDs required for the project. It also depends on the available space for the PCB.

It’s important to consider the size and shape of the PCB in relation to the overall design. For example, if the system is portable or wearable, a small, compact PCB may be more appropriate.

5. Design features

It is important to consider the design features of the SMD LED PCB. PCBs may include features like integrated resistors, which can simplify the design process and reduce the number of components.

6. Thermal considerations

Another important consideration when selecting an SMD LED PCB is the thermal management of the LEDs. SMD LEDs can generate a significant amount of heat, particularly high-power LEDs. Therefore, proper thermal management is critical to prevent damage to the LED and ensure optimal performance.

When selecting an SMD LED PCB, it’s important to consider the thermal conductivity of the PCB material. Also consider additional thermal management features, like thermal vias, that may be necessary to dissipate heat from the LED.

7. Manufacturing requirements

The manufacturing requirements of the SMD LED PCB are also important to consider. This includes factors such as the minimum trace width and spacing required for the PCB. You can add specific manufacturing processes, such as surface finishing or plating, that you may need.

It’s important to select an SMD LED PCB that you can manufacture using the preferred manufacturing processes and equipment. This can help ensure that you have produced PCB accurately and efficiently, minimizing the risk of errors or defects.

8. Environmental requirements

Must consider the environmental requirements of the SMD LED PCB when selecting the right PCB. This includes factors such as temperature range, humidity resistance, and exposure to chemicals or other environmental factors.If you use LED-based systemin in a harsh environment, select an SMD LED PCB which can withstand extreme temperatures.

9. Compatibility with other components

The compatibility of the SMD LED PCB with other components in the system is also an important consideration. This includes ensuring that the PCB is compatible with the driver circuitry and power supply.

It’s important to consider the voltage and current ratings of the driver circuitry and power supply. Must ensure that they are compatible with the voltage and current requirements of the LEDs and the PCB.

10. Cost considerations

Finally, it’s important to consider the cost of the SMD LED PCB when selecting the right PCB. The cost of the PCB will depend on several factors like size, complexity, and manufacturing requirements of the PCB.

It’s important to balance the cost of the PCB with the requirements of the project. Furthermore, ensure that the selected PCB provides the necessary features and performance while remaining within budget.

Whether you are working on consumer electronics, automotive applications, or industrial machinery, Hongda SMD Aluminum Electrolytic Capacitors are engineered to meet your specific needs. These capacitors provide stable and efficient performance, resulting in improved energy transfer and enhanced overall efficiency.